Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Normalizing of induction heating furnace for semi-finished products

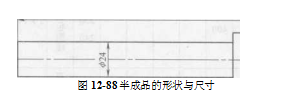

The processed semi-finished workpiece needs to be normalized. The shape and size of the workpiece are shown in Figure 12-880. The material is 20MnSi steel. The weight is 0.54kg. The required normalizing temperature is 1050Y. The productivity is 12 pieces/min, which is 388.8kg/ h

Because the work piece is of variable cross-section, the diameter of the small head is 24mm and the diameter of the big head is 41.3mm. The selected intermediate frequency power supply is 250kW and the current frequency is 2500Hz. The inductor used is a spiral cylinder, the induction coil has an inner diameter of 85mm and a length of 1800mm. It is wound with a rectangular pure copper tube of 14mm x 10mm x 2mm. The pure copper tube is not covered with an insulating layer. There is a certain gap between the turns of the coil. Air insulation, water cooling when working. The heat-resistant bushing in the induction coil is a quartz tube with an outer diameter of 60mm, an inner diameter of 50mm, and a length of 1800mm. The aluminum silicate fiber felt is lined between the quartz tube and the induction coil, the thickness of which is 12.5mm. 12 workpieces can be placed in the induction coil. There is no water-cooled guide rail. The workpieces are placed directly in the quartz tube and pushed into the material one by one. Every 5s, a workpiece is pushed in from the feed end of the sensor, and a workpiece heated to 1050°C is pushed out at the discharge end of the sensor. The terminal voltage of the inductor is 1400V, the heating time of the workpiece is 4min, and the temperature of the workpiece is basically the same, which meets the process requirements.

The characteristic of this induction heating furnace is that the terminal voltage of the induction coil is 1400V, the heat-resistant bushing is a quartz tube, and there is no water-cooled guide rail. The heating time of the workpiece is longer than theoretically calculated, which ensures the uniformity of the heating temperature of the workpiece .

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur