Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

At present, the refractory brick in the induction melting furnace in the prior art has a complicated structure, is inconvenient to disassemble and maintain, and has poor interchangeability.

Poor moisture resistance and temperature resistance. The purpose of the transformation is to solve the deficiencies in the prior art, and to provide a temperature-resistant refractory brick for an induction melting furnace with a simple structure and convenient operation.

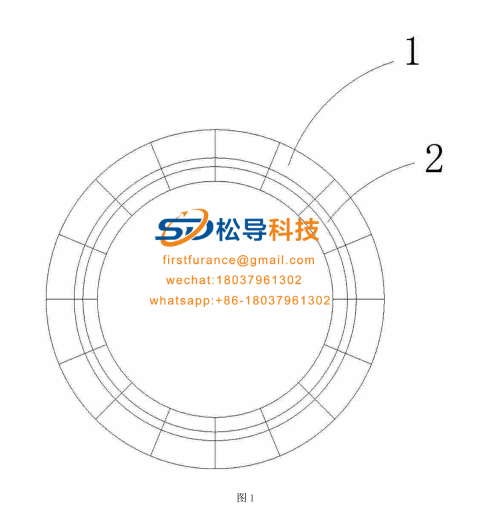

Mainly through transformation, the uniformly distributed refractory bricks are enclosed in a circle, and the refractory bricks are provided with cutout ring grooves, and the cutout ring grooves are annular. This structure is easy to install, has high interchangeability and strong moisture absorption and temperature resistance. Preferably, the refractory brick is fan-shaped, and the interruption ring groove is an arc groove. Therefore, the temperature-resistant refractory brick for an induction melting furnace of the utility model has a simple structure, convenient installation, strong versatility, and strong temperature resistance.

Figure 1 is a structural schematic diagram of the transformation of a temperature-resistant refractory brick of an induction melting furnace;

Concrete transformation method

The refractory refractory bricks of the transformed induction melting furnace include uniformly distributed refractory bricks enclosed in a circle, and the refractory bricks are provided with cutout ring grooves.

http://www.songdaokeji.com/plus/list.php?tid=22

http://www.songdaokeji.com

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur