Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

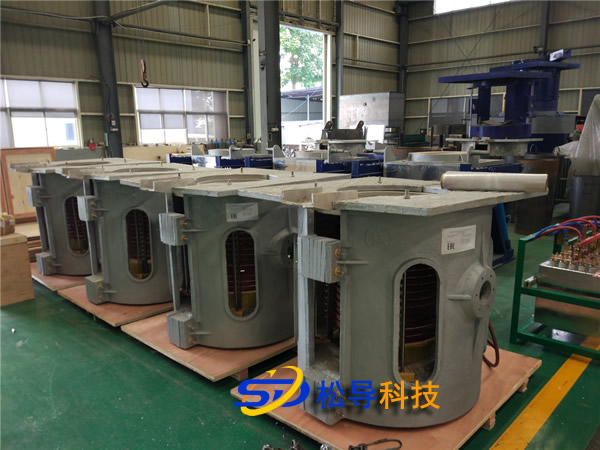

Installation, commissioning and final acceptance of 0.5 ton aluminum shell induction melting furnace

1. After the installation of the equipment on site, the on-site commissioning of the equipment shall be carried out when the water pressure test on the site determines that there is no water leakage and the power supply system can supply power normally.

2 , the seller expert on the site to the user equipment operation and maintenance personnel to carry out equipment operation and maintenance training.

3 , 0.5 tons of aluminum shell induction melting furnace final acceptance work should be at the user site, the acceptance of the project includes:

(1) All factory inspection items and comprehensive safety inspections;

(2) Measurement of power factor of induction furnace

(3) Measurement of induction furnace power, measurement of productivity;

(4) Measurement of power consumption and melting rate of induction furnace

(5) Measurement of the temperature rise of the cooling medium;

(6) Measurement of the temperature of the furnace component;

(7) Reliability and sensitivity check of the alarm system;

(8) Verification according to the provisions mentioned in the technical requirements;

After all the project inspection tests are completed, the final acceptance report will be written and the two parties will recognize the signature and take effect.

Quality control measures for 0.5 ton aluminum shell induction melting furnace

Our company has established a complete set of quality system documents in strict accordance with ISO9001 quality standards in quality control .

1.When selecting raw materials and external parts, our company has established a complete qualified sub-supplier to ensure the quality of raw materials and external parts.

2 ,in the production process, each component has a quality responsibility tracking card, indicating the responsible person of each processing step and the final inspector. For key components such as sensors, yokes, etc., there are special codes of practice to ensure that the parts that fail the upper pass never flow into the next process.

3 , the factory must be factory inspection before leaving the factory. The contents include visual inspection, mechanical size inspection, insulation inspection of induction coils, withstand voltage test and hydraulic test. The furnace operation check of the electric furnace, the inspection of the hydraulic system and the test of various parameters of the intermediate frequency power supply. After all the inspections are completed, the inspector fills in the product qualification certificate, and records the various test data to ensure that the product quality is traceable.

0.5 ton aluminum shell induction melting furnace product quality guarantee

1. This electric furnace equipment is manufactured with new high-quality materials that are compatible with the technical specifications of the equipment. All the substantive aspects are in accordance with the specifications of the equipment technical specifications.

2 , the main external parts of the equipment have the product certificate issued by the original manufacturer.

3.The electric furnace equipment is guaranteed for 12 months from the date of final acceptance . During the warranty period, if the equipment is faulty due to poor manufacturing or poor quality of the external parts, repair or replace the corresponding parts for the buyer free of charge.

4.Provide 24- hour response service. After receiving the user service request, the person will be sent within 24 hours.

5,to ensure the stability of parts production, long-term supply of spare parts to the user at a preferential price ( less than the market price of the same period ) .

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur