Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

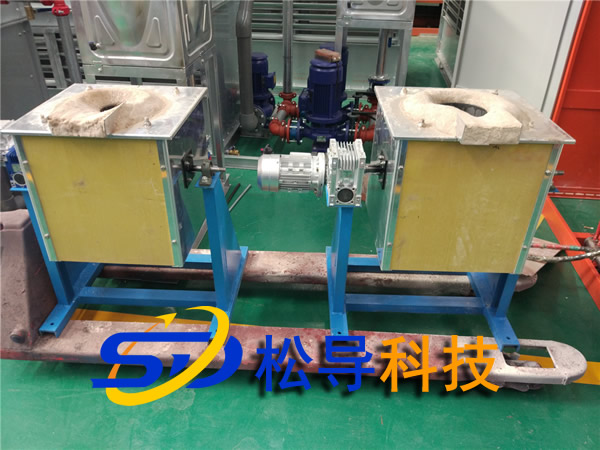

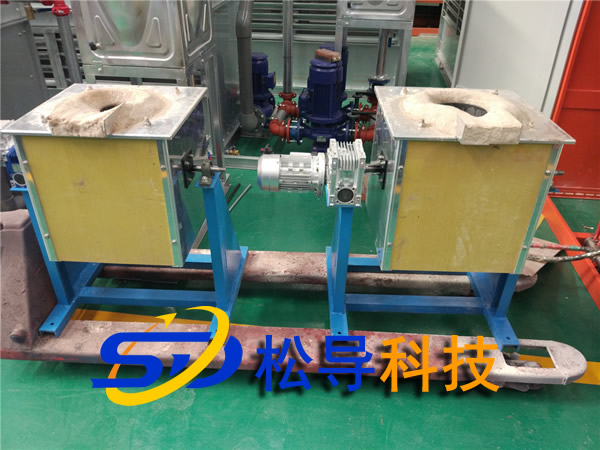

Weak magnetic material electromagnetic stirring electric furnace

1. Overview:

Sensing current and magnetic field generate electromagnetic force, because the thrust force acts in the direction along a traveling wave magnetic field and has a horizontal component and a vertical component, the molten aluminum can be inclined upward or fluidized phase, play the role of stirring, a phenomenon It is called electromagnetic stirring. Its important purpose is to mix metal solutions to produce a better homogeneous alloy.

The total amount of agitation depends on the size of the furnace, the kind and quality of the metal solution is added to the power of the furnace and molten metal frequency electromagnetic field. The disadvantage of agitation is that it causes the refractory lining of the furnace to gradually wear out due to the agitation of the molten metal colliding on the wall of the furnace. The result of wear and tear requires regular replacement of the lining. When the lining has been worn to its specified minimum thickness, it should be replaced quickly in order to prevent lining failure.

The advantage is that it has a stirring effect on the melted solution to make the solution more uniformly mixed . The temperature of the upper and lower parts of the melt can be made uniform, the stirring process does not destroy the oxide layer, the hydrogen absorption and oxygen absorption of the melt can be reduced, the melt quality can be ensured, and the composition of the complex alloy can be homogenized. Electromagnetic stirring is the non-contact stirring of the molten metal by electromagnetic force, and there is no contamination of the melt during the stirring process.

2, the implementation principle function of electromagnetic stirring electric furnace:

using two sets of coils to achieve vertical stirring, stirring in any stirring intensity, the stirring time, stirring direction, the working time of a single coil, can be set within the control system melting, and to achieve accurate temperature PID control.

3 , the intelligent control system description

The intelligent control system can centrally control the intermediate frequency heating equipment and mechanical devices. It is placed on the production site, which is beneficial to control the whole process of the heating process. On this basis, the contact temperature measuring device ( thermocouple ) and the PLC programming module are arranged , which can realize the control according to the aluminum melt temperature control and the intermediate frequency power control , as well as the stirring intensity , the stirring time and the stirring direction .

4, PID temperature closed-loop control system

Adopt international advanced PID temperature closed-loop control system, thermocouple temperature measurement, temperature accuracy \ 5 <C.

5, induction coil description

The induction coil is wound with a copper tube. In order to ensure the reliability of the induction coil, the copper tube adopts a high-quality cold-extruded copper tube with a thickness of 5 mm and a purity of 99.99% and a material of T2. The shape and spatial structure of the induction coil are designed according to the preferred results of electromagnetic induction numerical simulation. The 2 coils are wound clockwise counterclockwise . (The use of forward and reverse winding to avoid excessive gap between the coils to generate magnetic leakage)

The inductor consists of a water-cooled copper tube, a refractory layer, a protective layer, etc., and its number of structures is optimized by ANSYS simulation to meet the needs of frequency conversion.

6, the design requirements of the furnace body

Fixed furnace description

The furnace body part includes an induction heating coil, a structural body carbon steel, a yoke, an insulator, a heat-insulating material, a support frame, a fixed-point casting structure, and the like.

The fixed-point casting structure of the furnace body is installed on the supporting frame, and the furnace body and the hydraulic tilting furnace mechanism are designed according to the size of the atomizing tundish and the atomizing turret provided by the party A. The furnace body runs at a uniform speed, the height difference of the nozzle is small, and the liquid discharge is continuously stable. The running curve of the nozzle is fixed by the trajectory and optimized by the computer. The special curved template is used to guide the locking, so that the furnace body is uniformly and orderly discharged from the continuous liquid discharge to the fixed point. The tilting angle of the furnace body: 0゛95< (0< refers to the horizontal position of the furnace mouth); the furnace has high stability of turning, and the positioning accuracy of the discharging port is high (the distance between the outlet and the leakage of the melting furnace is less than 50mm), and the pouring center changes. The error is small. When the atomized steel is poured, there is no back and forth movement of the nozzle. The precision of the fixed point casting is high, and the front and back error does not exceed 30mm, and the stability of the metal liquid flow is ensured. The maintenance and replacement of complete sets of equipment are modular in design, easy to maintain and easy to overhaul, greatly improving production efficiency. Choice of crucible or knotting The products of Tianjin United Mine are resistant to fluoride salt corrosion and liquid aluminum alloy scour; and must not contaminate the furnace metal .

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur