Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

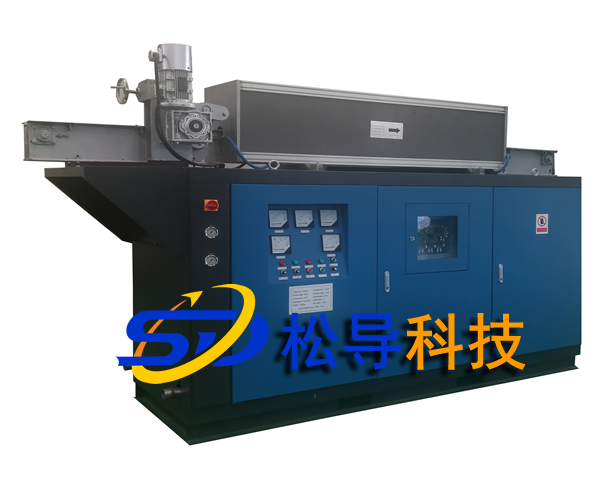

Automatic round steel medium frequency heating furnace

Automatic round steel medium frequency heating furnace

Fully automatic unattended medium frequency induction heating furnace with automatic loading and unloading, automatic feeding and discharging, automatic temperature control and temperature control sorting.

First, the round steel automatic medium frequency induction heating furnace workpiece parameters and process requirements

|

1 |

2 |

||

|

A. Production 1000kg / hour - 1500kg / hour B. Temperature 1050 ° C -1100 ° C C. Core surface temperature difference <20 ° C |

Φ120×180 |

A. Output 1500kg / hour - 2000kg / hour B. Temperature 1050 ° C -1100 ° C C. Core surface temperature difference <20 ° C |

Φ 80×110 |

|

Φ 120×240 |

Φ 90×200 |

||

|

Φ 140×210 |

Φ 140×210 |

||

|

Other requirements: temperature visualization, loading and feeding automation. The incoming transformer capacity is 400KVA. |

|||

Second, round steel automatic medium frequency induction heating furnace system equipment configuration:

1. Brief description:

After manually discharging the workpiece on the inclined upper material table, the material is fed through the scraping board, and the material is placed in place, and then the workpiece is turned into the induction furnace mouth feeding trough by the turning system, and then the pushing cylinder is set. The beat is pushed into the heating furnace, and the discharge port is quickly introduced by the rapid extraction system into the next forging process. The infrared thermometer detects and displays the temperature.

2. Device Configuration:

The scope of supply of equipment supporting equipment is as follows:

|

|

name |

regulation grid |

Quantity |

Remarks |

|

1 |

Intermediate frequency power supply |

KGPS-350/0.5 |

1 set |

|

|

2 |

capacitor bank |

|

1 set |

|

|

3 |

Heating furnace |

GTR140×4000 |

1 set |

Heating workpieces with Φ 140-120 |

|

|

GTR90×4000 |

1 set |

Heating workpieces with Φ 90-80 |

|

|

GTR270 |

|

Heating Φ 270 workpiece |

||

|

4 |

Scraper |

dedicated |

1 set |

|

|

5 |

Turning mechanism |

dedicated |

1 set |

|

|

5 |

Quick discharge machine |

dedicated |

1 set |

|

|

6 |

Infrared Thermometer |

Domestic |

1 set |

|

|

7 |

Temperature display instrument |

|

1 set |

|

|

8 |

External console |

|

1 set |

|

|

9 |

Cylinder feeding mechanism |

dedicated |

1 set |

|

|

10 |

Connecting cable and copper bar |

|

1 set |

|

Note: 1. The complete set of equipment can also choose Siemens PLC and operation screen for the whole process control of equipment production, with parameters display, recording, query, alarm and other functions; temperature control using advanced mathematical model calculation, power factor self-correction The control method can achieve better control of batch temperature stability. This item is an optional item, which can increase the grade of the equipment. The price of all added software is 80,000.

2. The complete set of equipment can also be equipped with a Feng Shui cooler (FL-500) for cooling.

Fives, Round steel automatic medium frequency induction heating furnace equipment technical indicators and technical characteristics

1, the startup success rate can reach 100%

2, the rectification power factor is greater than or equal to 0.96

3, with temperature interface can achieve temperature closed-loop control

4, with internal and external conversion and automatic manual conversion function

5, multi-station structure can be easily and quickly replaced according to different heated workpieces

6, Full digital, no relay control loop, making the system stable and reliable

7, with over-current, over-voltage, under-pressure, phase loss, water pressure, water temperature and other complete protection, to ensure that any failure does not damage the equipment components

8, three-phase incoming line does not distinguish the phase sequence, can be connected arbitrarily

9, easy to operate "fool" type equipment, never misunderstanding

10, furnace structure

For different heated workpieces, different heating furnaces should be replaced when heating. In order to facilitate the replacement and reduce the workload when replacing the furnace body, our heating furnace is designed as a whole type.

The water connection is a quick connector, and four bolt connections are used for electrical connection. Simply replace the bolt and open the water fitting locking device when replacing.

11. Quick-change joint: For the convenience of operation, a quick-change joint is adopted in the design of each water pipe joint.

12. Furnace lining: The furnace lining adopts silicon carbide or integral knotting method. The use temperature is above 1450 °C, which has good insulation, heat insulation, and resistance to chilling heat and impact resistance.

Protection: The temperature switch is installed on the sensor coil, and it will stop automatically when the water temperature exceeds 65 °C. Avoid burning the induction coil. When not working, the condensed water in the inductor coil can be discharged through the compressed air;

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur